- Testing of solar cells is used for testing and recording the results of testing mono- or poly cells (crystals), which the enterprise receives as input raw materials.

- Cutting of solar modules according to design parameters..

- Preparation of copper-tinned alloy tape with the help of straightening and forming a fixed length of the conductor.

- Soldering of solar cells, which burns at automatically puts solar modules in rows.

production

Our production process includes all stages – from the selection of the best materials to the final assembly of the panels. We use high-quality silicon, which ensures maximum performance and longevity of the panels. And the production meets the highest quality standards, using advanced technologies that allow to ensure stability and efficiency.

PRODUCTION OF PANELS

-

Production of solar PANELS

-

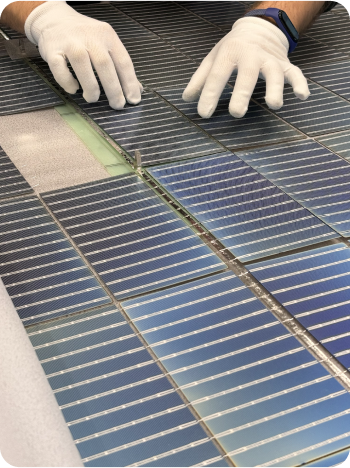

Assembling solar cells in a panel

- Assembly of modules: Solar mono- or poly elements (crystals) are connected to each other with the help of special conductors, creating a circuit. Usually 60 or 72 elements (crystals) are used in the panel.

- Lamination: Elements (crystals) are placed between two layers of transparent film (usually EVA – ethylene vinyl acetate) and covered with protective layers of glass or polymer on the front and a strong base on the back. Then all this is laminated under high temperature and pressure, which ensures tightness and protection of elements from moisture and mechanical damage. At the exit from the laminator, the EVA glass residue is trimmed and prepared for framing

- Frame and connection: The panel is fixed to an aluminum or steel frame for additional mechanical support. Connectors for electrical connections are installed in the frame, allowing you to connect the panels to larger systems.

-

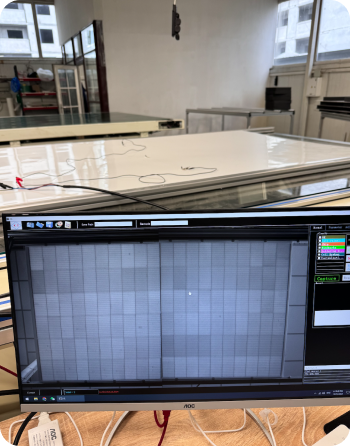

Testing and certification

Once manufactured, each panel undergoes rigorous quality tests to ensure its effectiveness and reliability. Here are some types of testing::

- Testing mono- and poly crystals for integrity and entering indicators.

- Laboratory performance testing: Each panel is laboratory tested under standard lighting conditions (STC) to verify its rated output.

- Mechanical tests: Panels are tested for resistance to wind, hail, snow and other natural influences. The ability of the panel to withstand harsh weather conditions is important, especially in conditions of high wind loads and temperature changes.

- Moisture and Corrosion: Moisture and corrosion tests are especially important for panels that will be installed in regions with high humidity or in coastal areas.

-

PRODUCTION OPTIMIZATION

In modern factories, automated control systems, robotic lines and software for managing production processes are widely used. This allows:

- Reduce the number of defects: Automation minimizes the human factor, which reduces the number of defects and increases the overall quality of products.

- Optimize costs: Using robots and automated lines reduces manual labor costs and increases productivity.

CERTIFICATES AND LICENSES

We pay special attention to each stage of the production process, so we regularly undergo inspections and checks for compliance with quality and environmental standards. Thanks to this, our solar panels meet the requirements for energy efficiency and safety, which allows their use both for private homes and for large industrial facilities.

Our certificates guarantee that you receive proven and reliable products that have passed all the necessary tests and have official permission for use.

-

CERTIFICATE

-

CERTIFICATE

-

CERTIFICATE

Consultation

Need more information?

Get a detailed consultation